As seasoned building contractors or avid DIY enthusiasts, understanding the critical role of roofing screws in ensuring a sturdy and durable roof installation is paramount.

In this comprehensive guide, we delve into the nuances of selecting roofing screws tailored for both metal and timber roofing materials, facilitating informed decision-making for your upcoming projects.

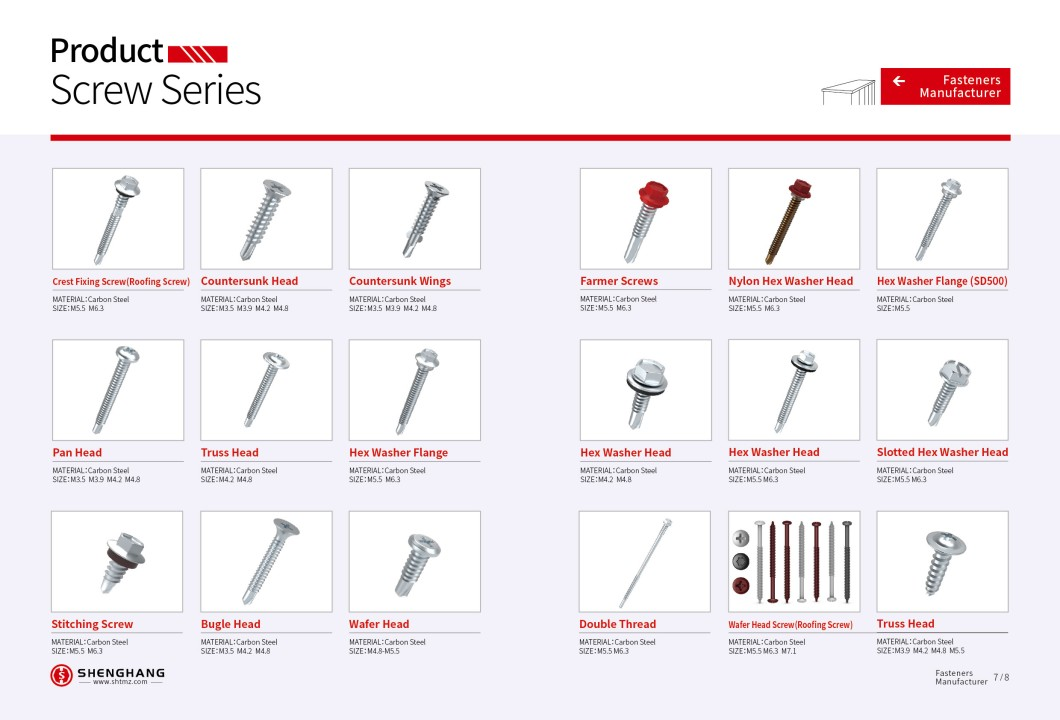

Roofing screws are engineered to anchor roofing materials securely, thereby safeguarding against potential structural vulnerabilities. They are available in diverse types, each meticulously designed to accommodate specific roofing materials and application requirements.

Specially crafted for metal roofing panels, sheet metal screws boast an array of sizes and head styles, catering to varied project specifications. Fabricated from galvanized steel or aluminum, these screws exhibit exceptional resistance to rust and corrosion, ensuring longevity and structural integrity.

Engineered for wooden roofing materials, timber screws are predominantly crafted from galvanized steel. Available in assorted lengths and diameters to accommodate varying thicknesses of roofing materials, these screws offer robust anchorage and enduring performance.

When embarking on the selection process for roofing screws, several pivotal factors warrant consideration to optimize efficacy and longevity of the roofing installation.

The inherent characteristics of the roofing material dictate the suitability of specific screw types. Sheet metal screws seamlessly complement metal roofing panels, while timber screws are tailored for wooden roofing substrates, ensuring compatibility and optimal performance.

In regions characterized by adverse weather phenomena such as high winds or heavy precipitation, prioritizing screws engineered to withstand corrosion and rust becomes imperative. Opting for galvanized steel or aluminum screws reinforces resilience against environmental elements, fortifying the structural integrity of the roofing system.

The weight and dimensions of roofing panels necessitate meticulous consideration during screw selection. Optimal screw length and diameter are paramount to penetrate the roof deck adequately, facilitating secure fastening and mitigating risks of structural compromise or dislodgment.

Employing roofing screws confers an array of benefits, underscoring their indispensability within roofing projects of varying scales and complexities.

Roofing screws engender robust and steadfast connections, pivotal in prolonging the lifespan of roofing installations. Characterized by resistance to rust and corrosion, these screws offer unparalleled durability, particularly in regions susceptible to harsh climatic conditions.

The user-friendly nature of roofing screws facilitates expedited installation processes, accommodating both seasoned professionals and DIY enthusiasts. Compatible with cordless drills or impact drivers, roofing screws streamline installation procedures, optimizing efficiency and minimizing labor-intensive tasks.

Cost-efficient alternatives to traditional roofing fasteners such as nails or adhesive, roofing screws present a budget-friendly solution without compromising on quality or performance.

Available in bulk quantities and readily accessible, they present a financially prudent option for roofing projects without compromising structural integrity or longevity.

In summation, roofing screws constitute an indispensable component of roofing projects, pivotal in ensuring steadfast anchorage and enduring structural integrity.

By discerningly evaluating factors such as roofing material, climatic conditions, and panel dimensions, informed decisions can be made, culminating in optimal outcomes and fortified roofing systems.

Roofing Fastener Market: A Comprehensive Guide to Quality Roofing Screws in the U.S. and Canada

2024-01-25Top-Rated Roofing Fasteners: A Wholesaler's Buying Guide for European Contractors

2024-01-05Empower Your Projects: A Comprehensive Guide to Fastener Strength, Finishes, and Trusted Suppliers

2024-01-05The Ultimate Guide to Fastener Coatings: Choosing the Right Coating for Optimal Performance

2024-01-05

Tel: + 0086 15076176199 + 0086 311-87880324

No.3 Mingdu International Building,

Economic and Technological Development

Zone, Linyi

Shandong China

Shandong Shenghang TECHNOLOGY CO.,Ltd